How sand is turned into a moulding

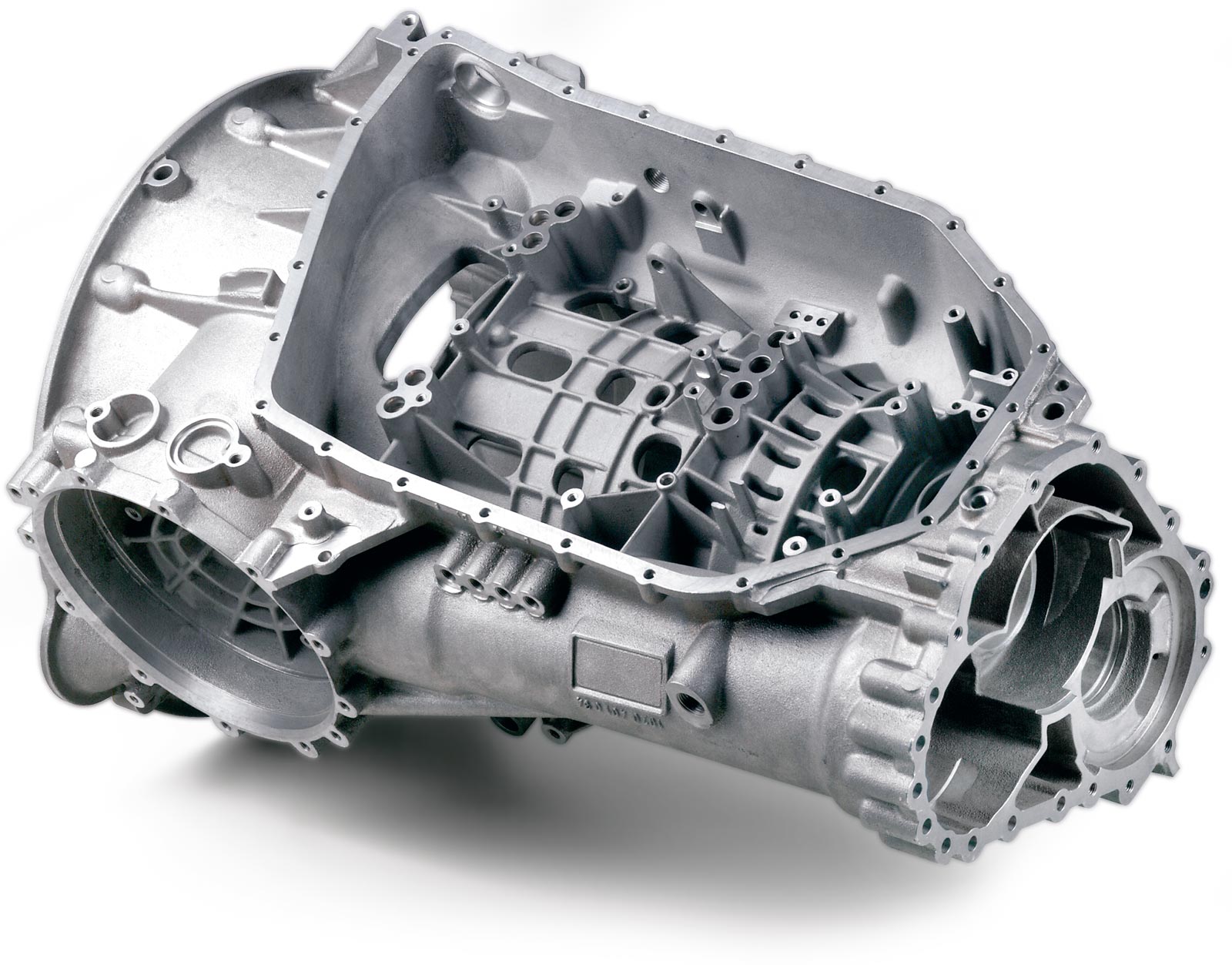

The cores form the heart of the casting, enabling almost unlimited design possibilities in the casting process.

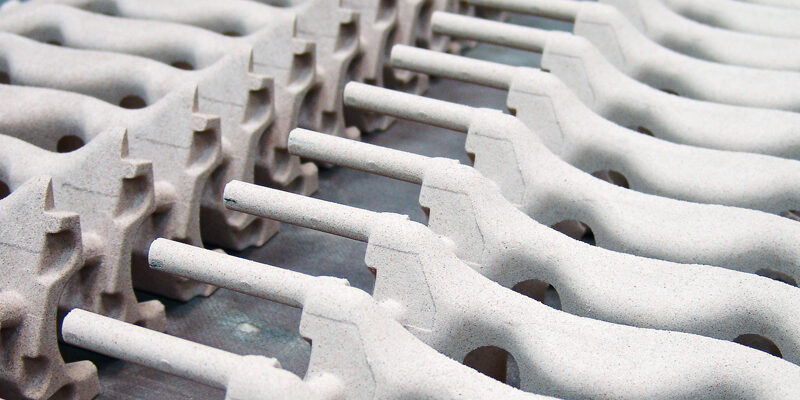

The core making requires a lot of expert knowledge and long-term experience. Not only long-lasting and solid stability has to be achieved but also secured mold emission upstream must be guaranteed.

The cores are later used to design the cavities in the casting. They basically make it possible that undercuts are reproduced later. All in all, the cores are necessary for the multiple design possibilities of the moulding process.

Our modern and sophisticated machines and equipment are of the latest generation and it goes without saying that they are in compliance with ecological standards and environmental protection.

For the core moulding the process of core building blocks is possible as well.

This process is suitable for the production of prototypes in order to achieve surfaces similar to die casting.