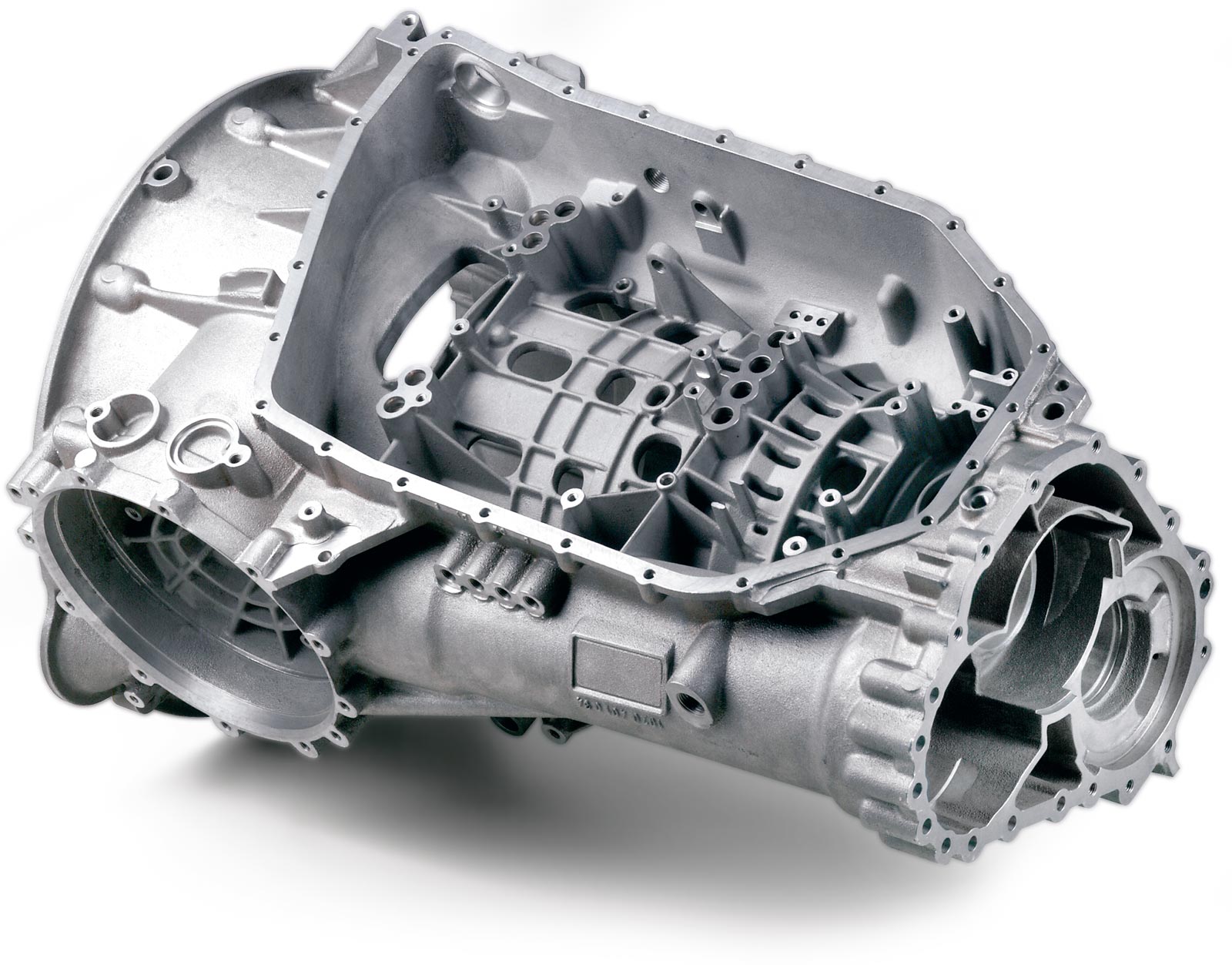

Sand-printed moulding

To ensure fast and economical manufacturing of prototypes, we have been using the sand-core printing technology since 2011. This method makes it possible to produce a casting without moulding.

During the additive 3D printing procedure one thin sand layer after the other is spread on a flat surface and held together by means of chemical binding agents.

This procedure makes it possible to print a finished casting mould only out of 3D data quickly and accurately. The calculated casting parameters in terms of runner, feeding and gating techniques can be considered even during the construction phase. The digital manufacturing is especially suitable for the production of prototypes. Even complex and thin-walled sand outlines can be displayed without any problems. The same applies for the manufacturing of spare parts which can be produced quickly and easily without any tools.

Another advantage is the environmental sustainability. The sand is reprocessed directly after the casting process and flows back in the sand system again.